I guess this is long overdue an update!

The grinding issue was resolved after taking a breather from the car - one of the steel wheels had somehow seated slightly off centre, so that was an easy fix in the end.

The car has mostly been in constant service since then, with only some minor breakdowns that it has always managed to limp home with.

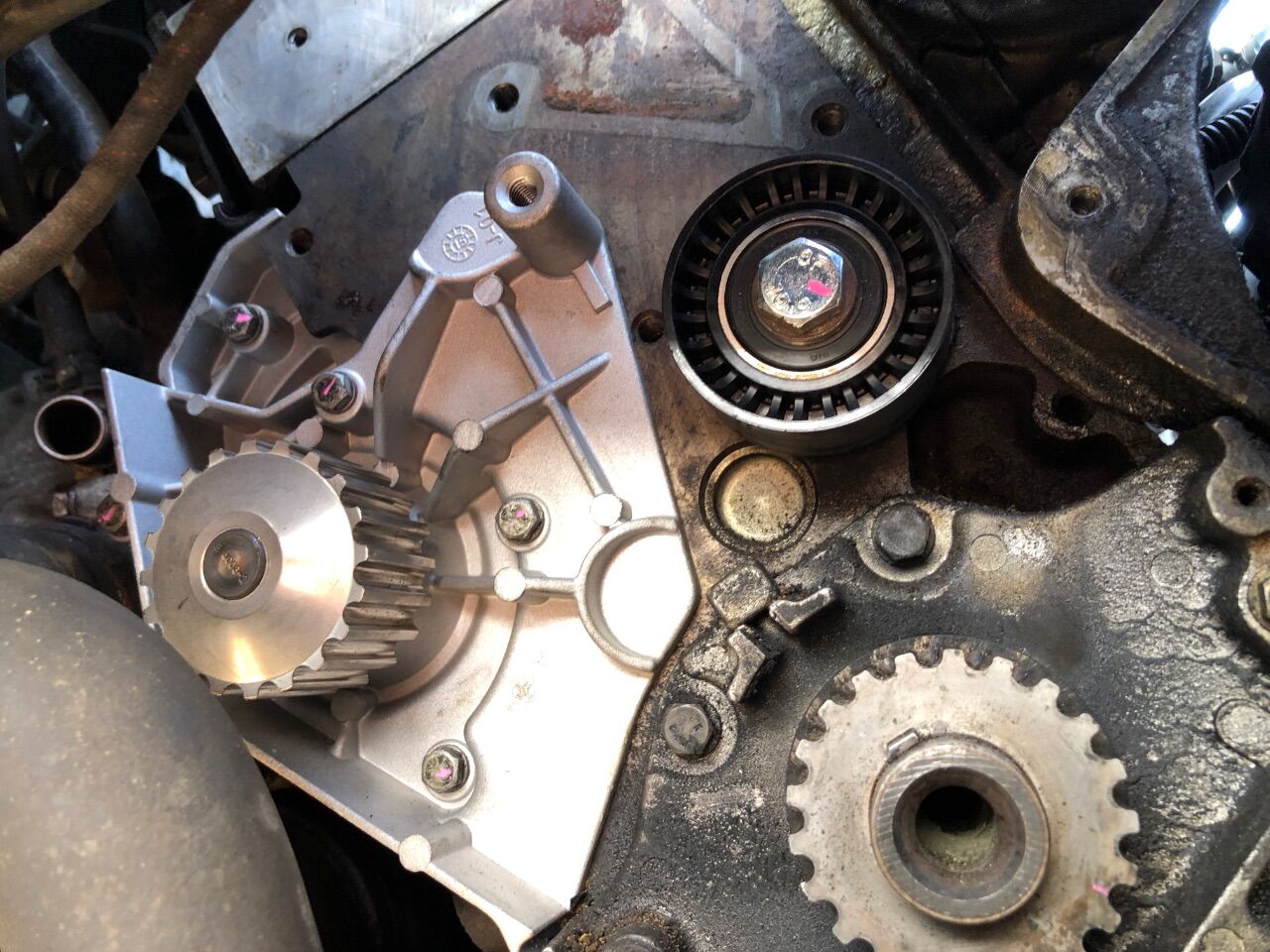

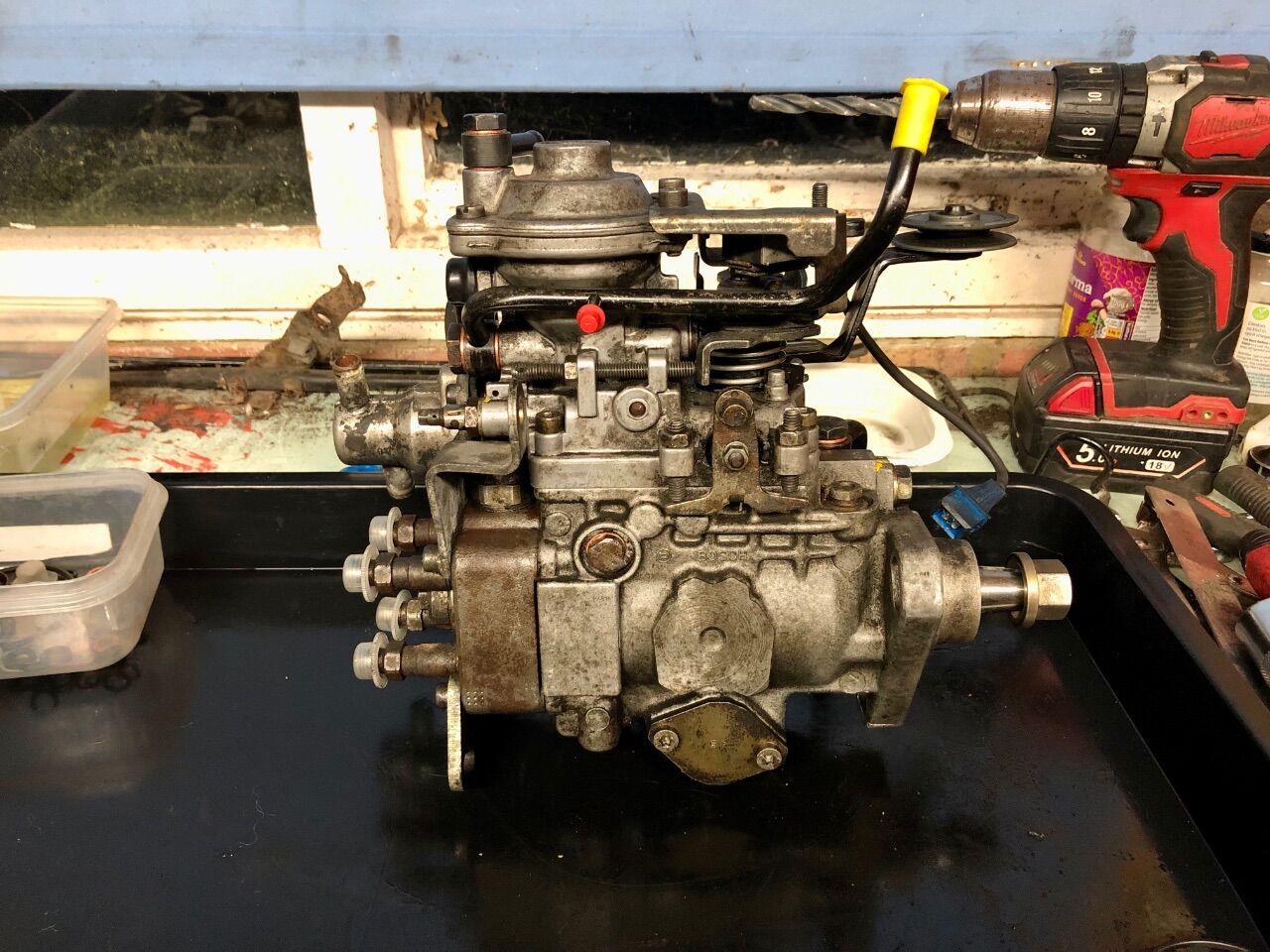

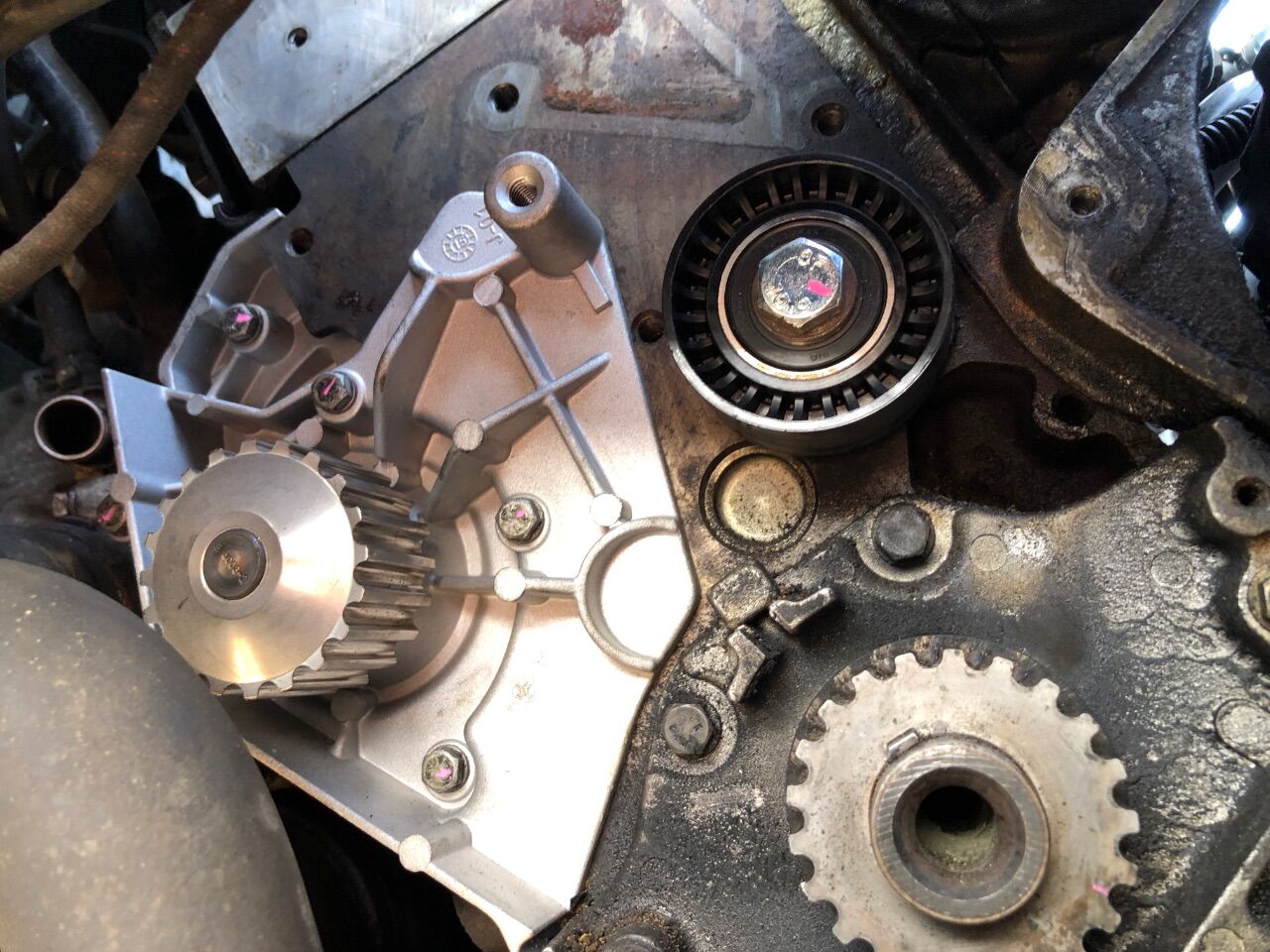

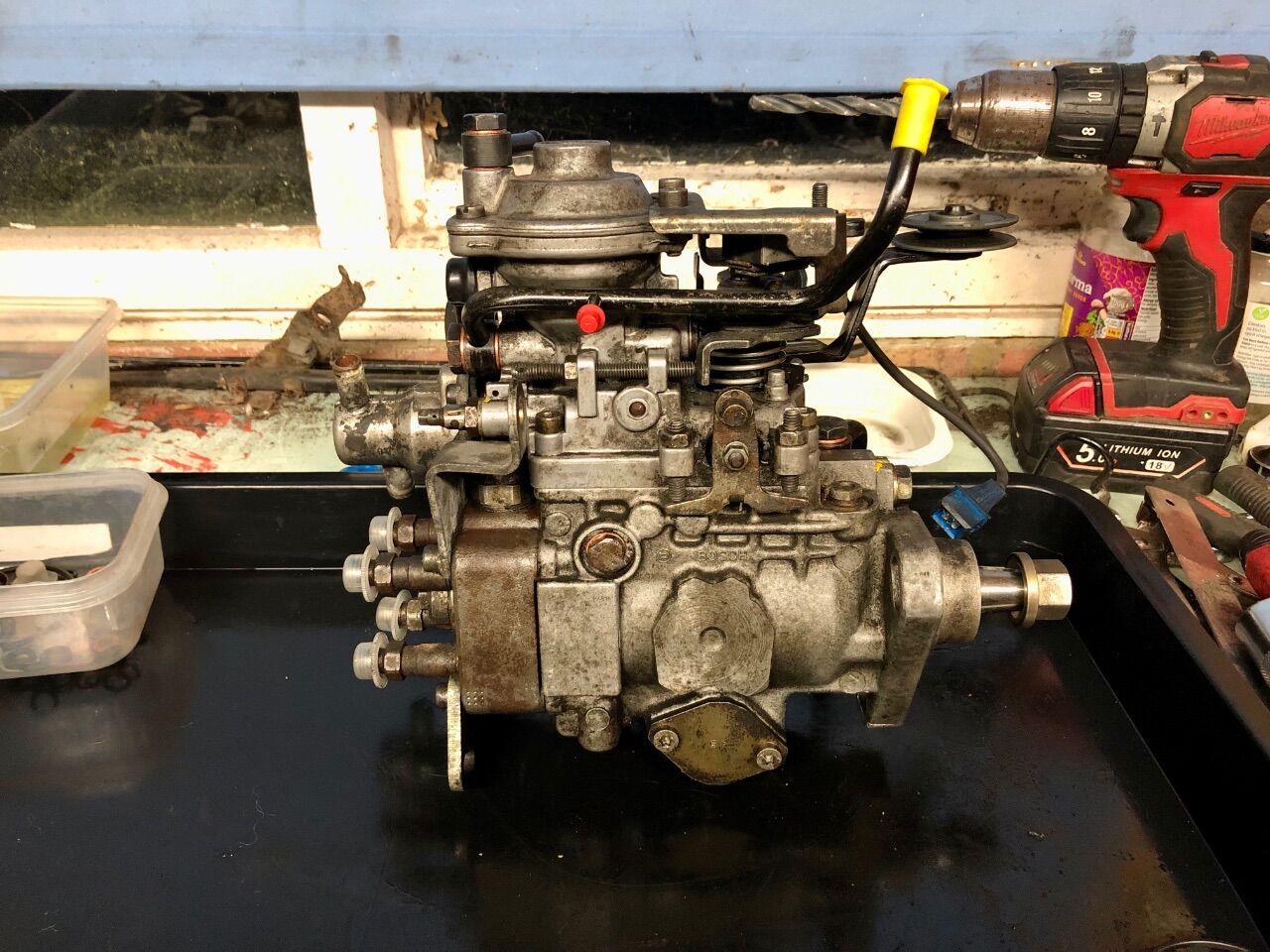

Recently the fuel pump developed a pretty major leak between the pump housing and the metering head, so I decided to pull the pump out, rebuild it, and do the timing belt, water pump and thermostat too.

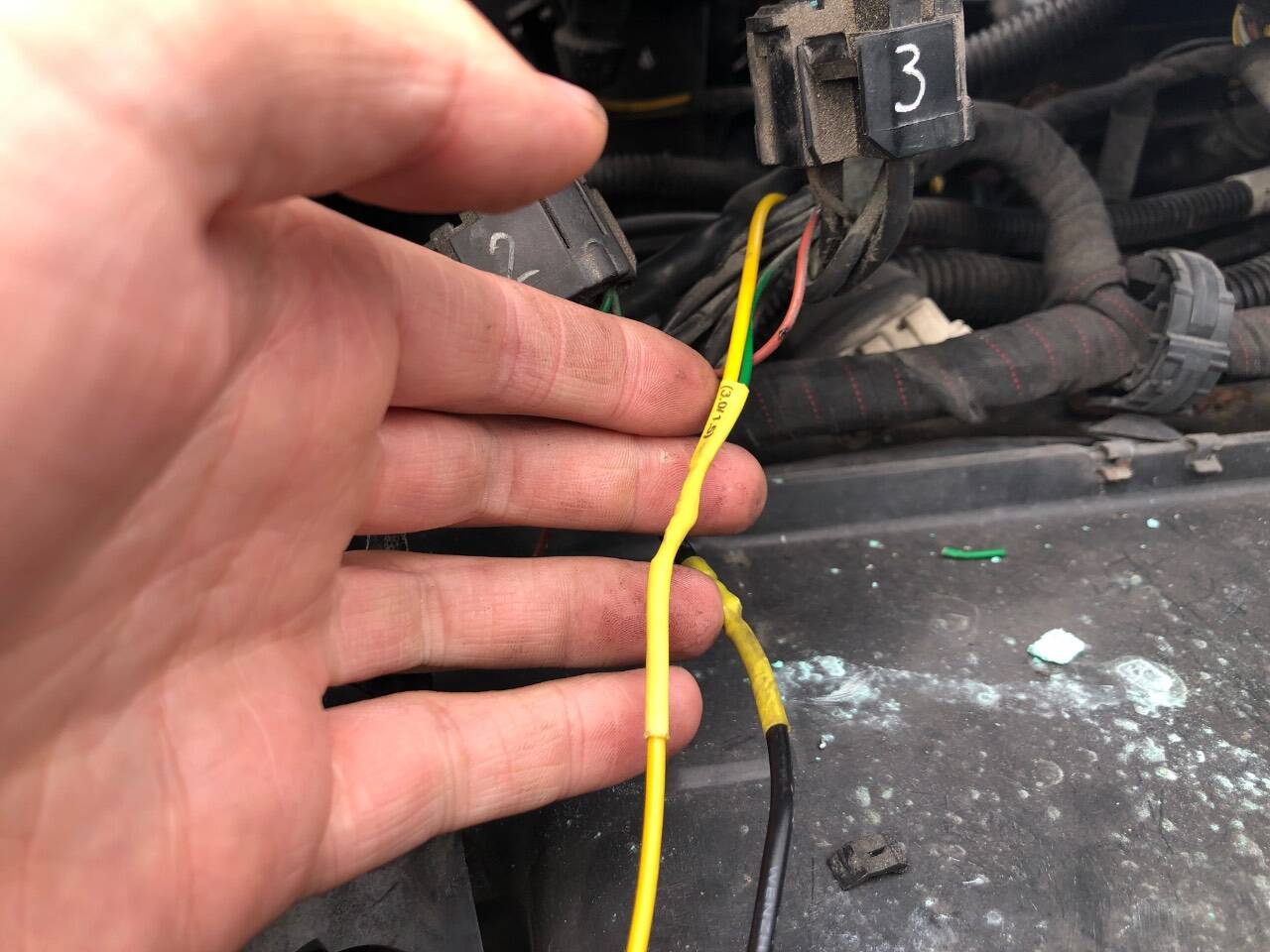

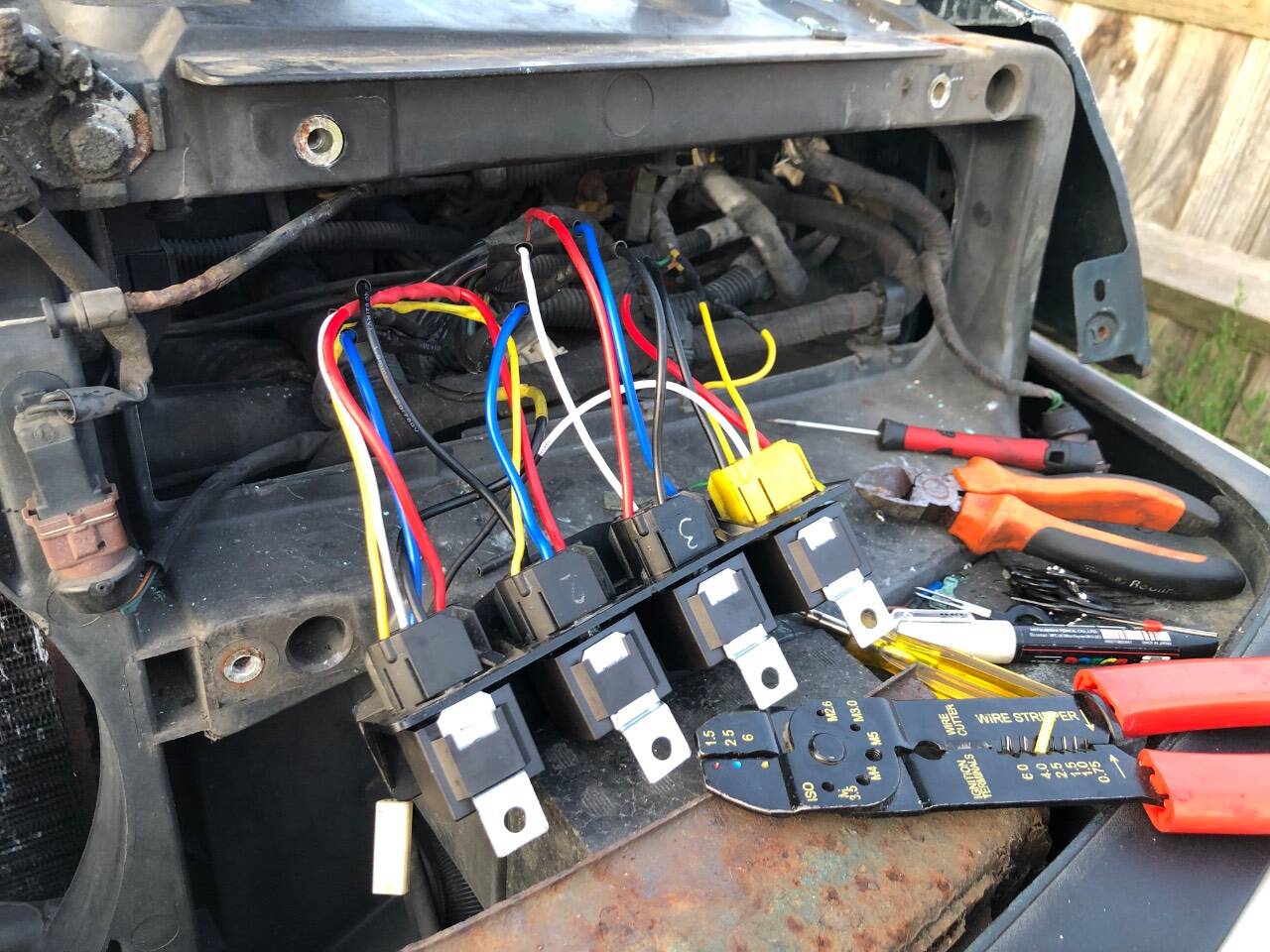

The timing belt, water pump and thermostat have been completed without anything of note, as has the pump rebuild. The pump is back on the car, and whilst it is now definitely fluid-tight, I still have issues with slow starting. I've narrowed this down to either the earth cable or starter circuit, as even with a fresh battery the starter is labouring and the battery terminal gets hot. I've got some spare battery cable here, I'll replace the old one tonight and I will also wire in a relay for the starter - hopefully that resolves that issue.

However, whilst doing this work I have decided to attend to the ABS system, as I've got good access at present due to how much I've removed from the engine bay. This is where I'm meeting with some trouble.

When the ignition is switched on, the ABS light turns on. It does not flicker, so I don't believe it is performing any of the self test functions.

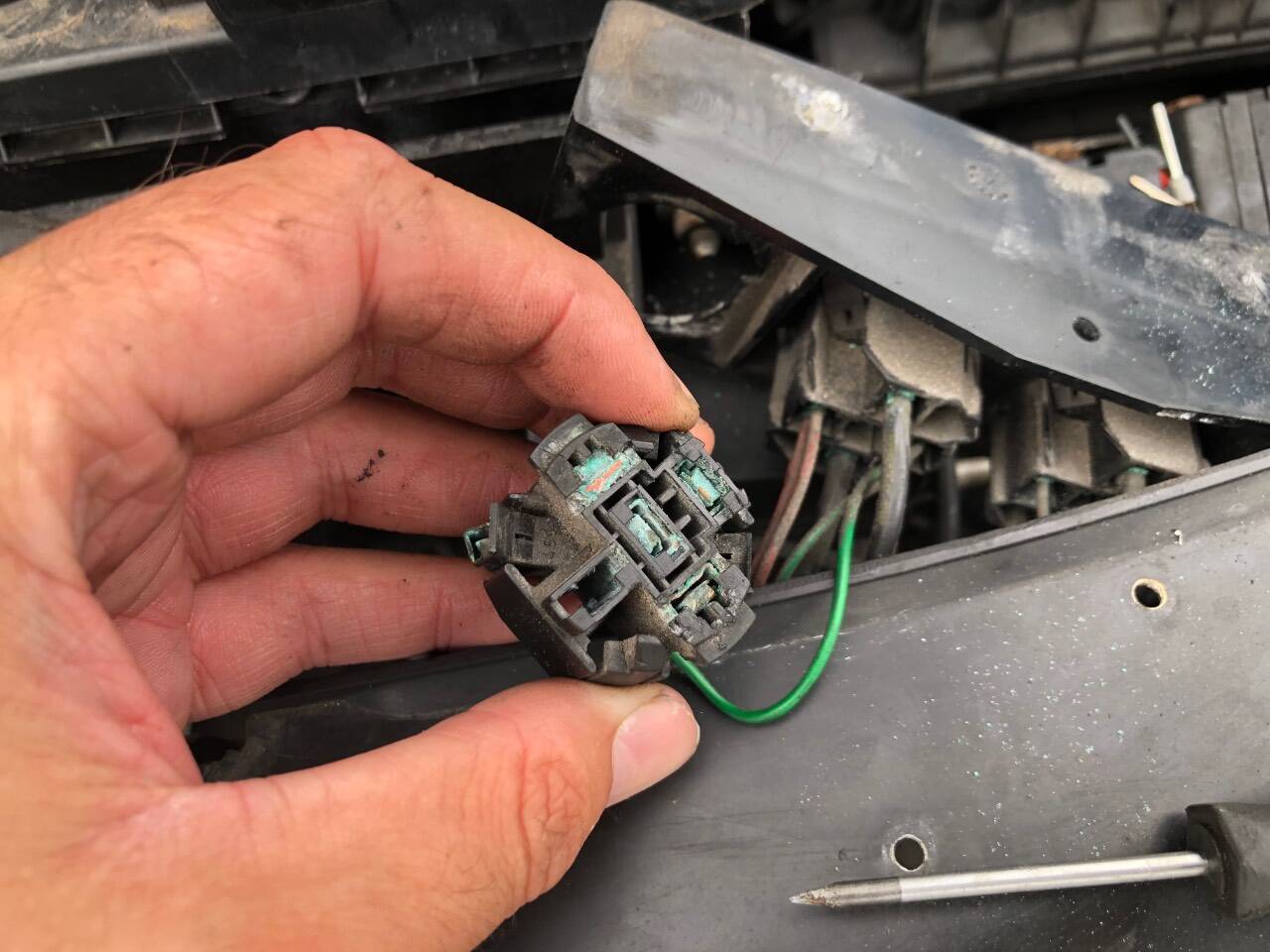

I have tested the relay on my solenoid block (it's the sealed unit Bendix type), and the relay works and the circuit is made/broken as expected.

I have tested all the feeds and earths for both the ECU and the solenoid block. All of these are showing continuity between connectors, and either showing a good earth, or +12v when required.

However, I cannot see that the ECU ever sends a signal to the solenoid block relay coil in order to switch it from earth to +12v through the 30a.

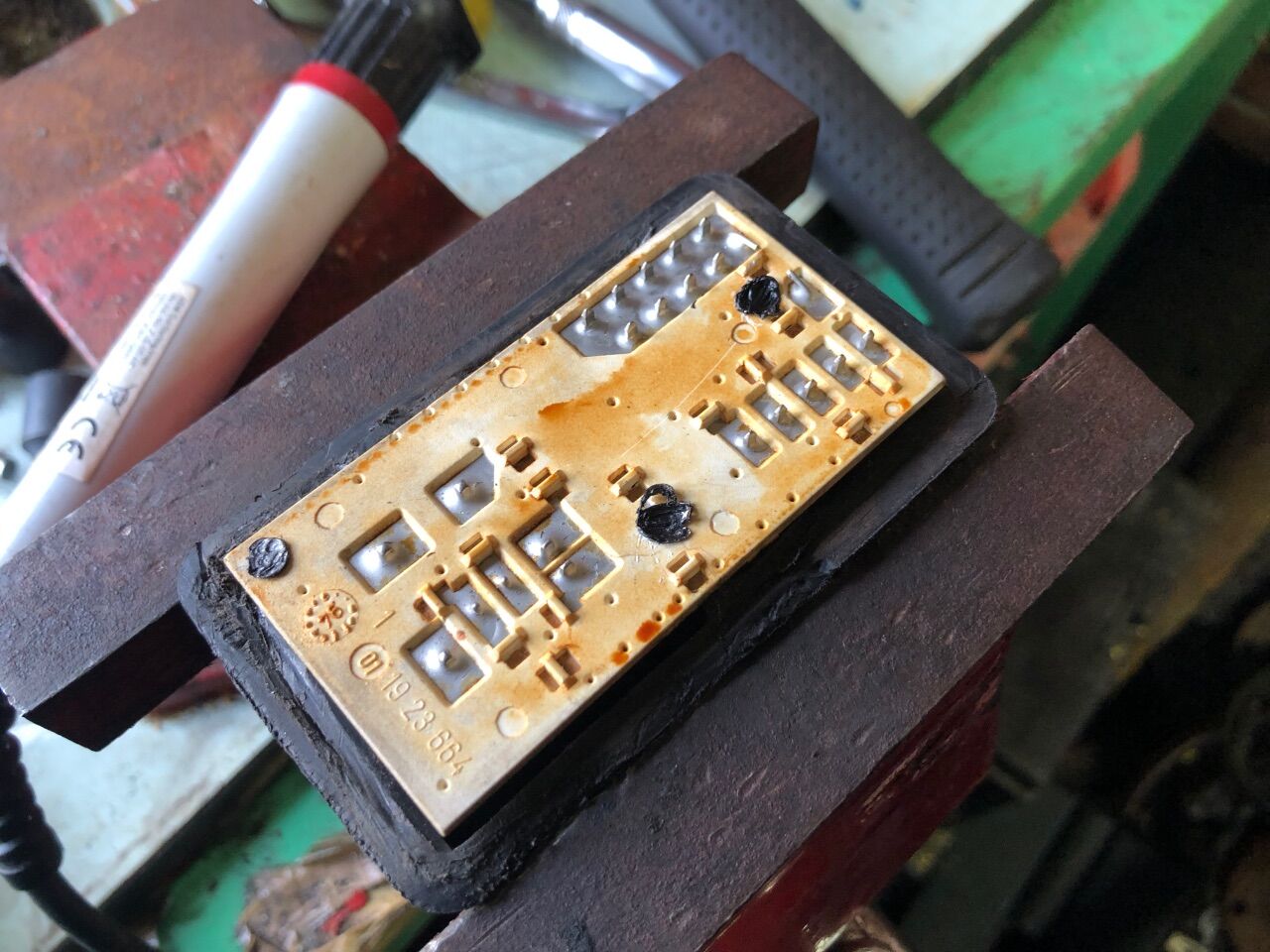

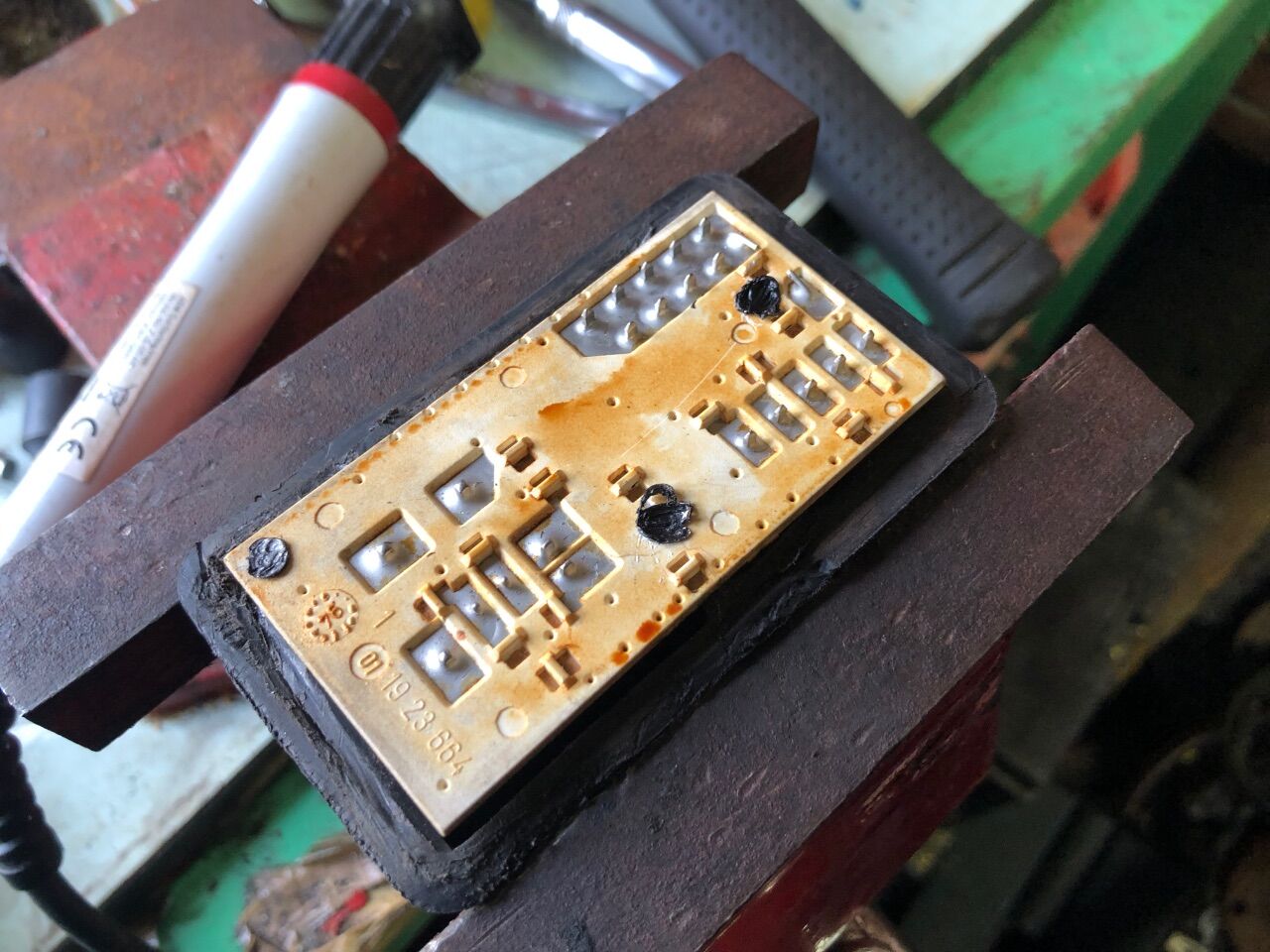

I have opened up the ABS ECU to check if there was anything obviously wrong inside, but the only electrolytic capacitor present is absolutely fine and there isn't really anything else inside testable other than perhaps the transistors.

I'm unsure where to go from here; I don't want to blindly chuck parts at the car, and my gut feel is still that this may not be a problem with the ECU. I'm just unsure where I can go with the testing from here...